Electrowetting-on-dielectric (EWOD)

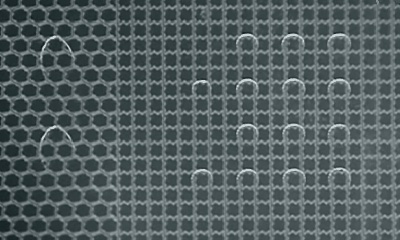

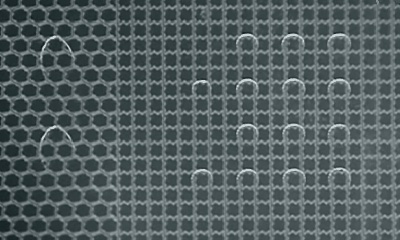

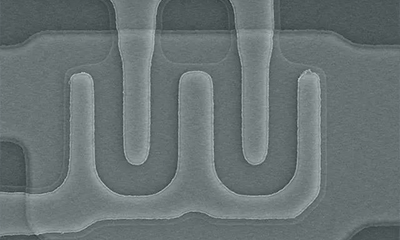

Digital microfluidics (DMF) is a liquid-handling technique based on droplets. The droplets on the chip serve as transporters for a variety of reaction materials, including biochemical reagents, cells, proteins, DNA, and RNA. DMF allows software-reconfigurable operations on individual droplets, such as move, combine, split, and dispense from reservoirs by manipulating picolitre to microlitre droplets in electric fields. Meanwhile, it can accommodate a variety of experiments because of its modular functional components (temperature control, magnetic attraction, fluorescence detection, etc.).

Thin film transistor (TFT)

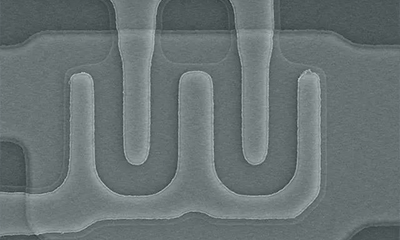

TFT is an active switching element in large-area electronics technology. It is brought in as digital microfluidic chip's basic circuit unit, turning the droplet driving electrode on and off. Currently, there are three types of mature TFT technologies: a-Si (amorphous silicon), LTPS (low-temperature polysilicon), and IGZO (indium gallium zinc oxide). Corresponding TFT technology can be flexibly selected based on required chip performance and cost.

Flat-Panel (FP)

ACX inst's chip manufacturing process is compatible with flat-panel technology, which was originally utilized in the display industry, achieving a complex integrated circuit structure depending on high-precision and mature semiconductor manufacturing processes. Our chip can reach nearly 100% yield by collaborating with display flat-panel manufacturers expertizing on large-scale TFT Flat-Panel production technology, Automated Optical Inspection (AOI), and Laser Repair technology.